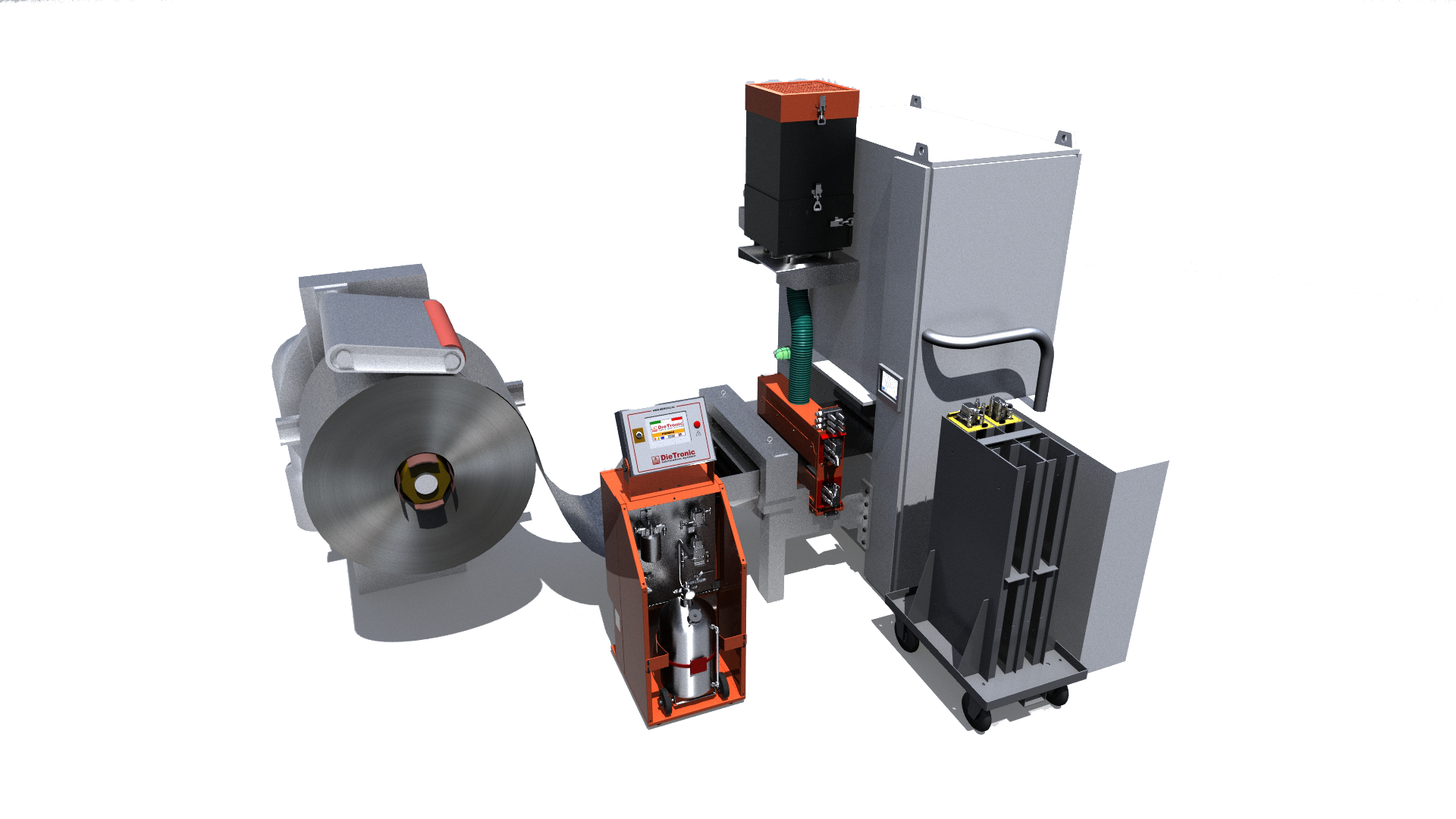

• Flexible spray lubrication systems

• Ideal for progressive stamping and small part production

• Spraybox design to cover coil widths from 200mm to 800mm

• Additional single spray valves (lubo-die) available, to

re-lubricate critical areas, typically in the mold

OIL MIST SUCTION SYSTEM

PROGRAMMABLE PLC AND TOUCH-SCREEN OPERATOR INTERFACE TO MANAGE THE LUBRICATION PARAMETER

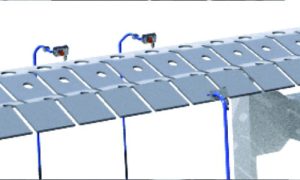

FOR IN-DIE LUBRICATION

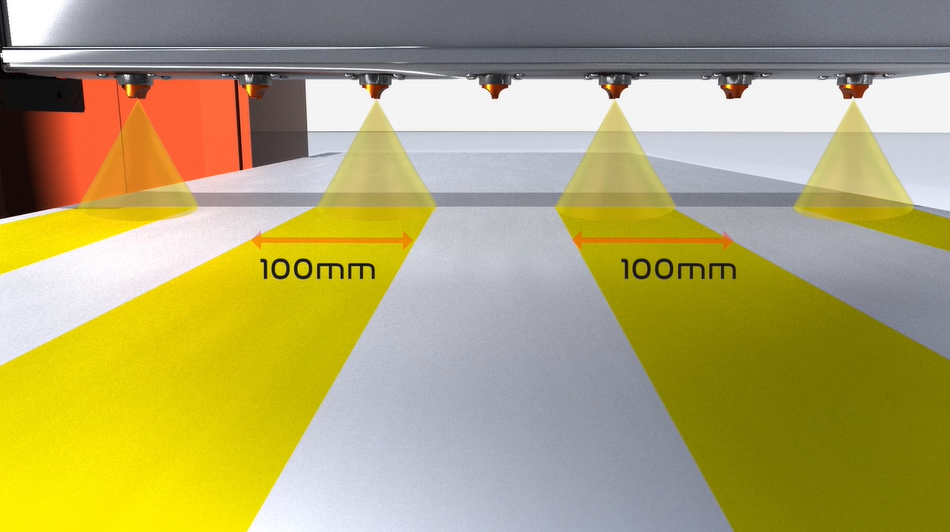

VERSATILE POSITION OF THE SPRAYING NOZZLES ON THE STAMPING DIE

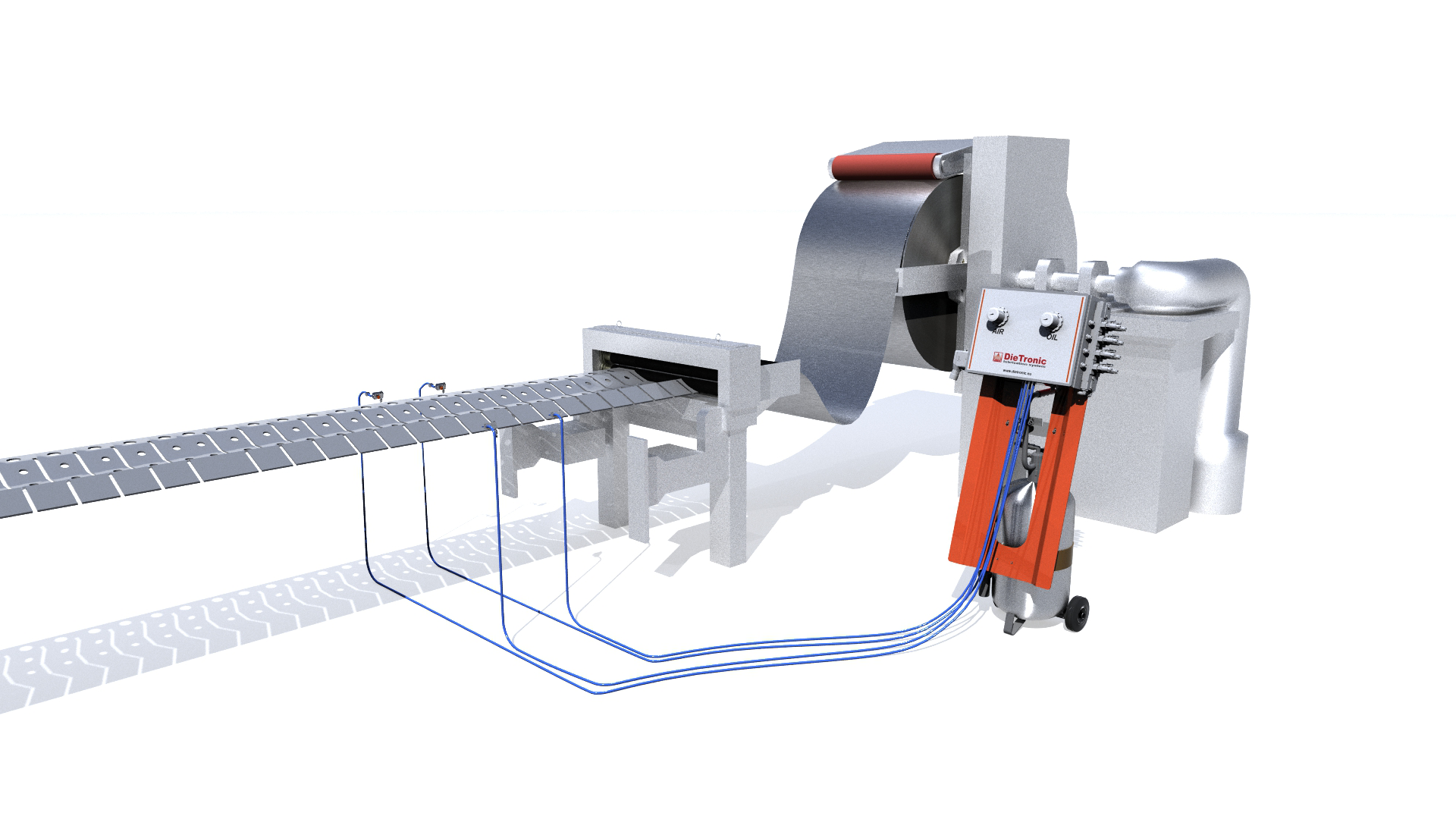

The Promax spray system enables automatic strip lubrication, allowing the selection of certain areas on which to apply the

lubricant. Its configuration is intentionally very simple and versatile: the standard system consists of a closed spray box (available

in various sizes depending on the width of sheet metal to be processed), which helps to reduce the dispersion of the lubricant in the

surrounding environment. A 24-litre pressurised tank equipped with wheels. Design of the pressure vessel permits filling of the tank

directly from the barrel, thus preventing external contaminents being introduced into the oil; this removable tank feature also gives the

possibility to use multiple oil tanks to manage different oil requirements.

To complement the basic configuration, DieTronic has thought about the possible integration of additional components: among these

options, an oil mist suction system and a level sensor, to be affixed to the tank, which warns the operator when the tank is almost

empty; finally the Lubo-die unit can be considered an intergratable accessory that allows specific points within the die tooling to be

re-lubricated.

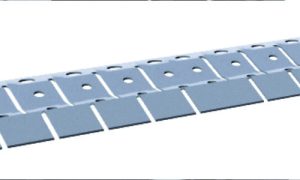

All systems in the DieTronic portfolio, grant a correct and controlled application of lubricant, so that the coil or blanks can receive the

optimal amount of lubricant at the most critical points, reducing the consumption without causing scratches that could impact the

quality of the finished product. This precise control also improves the quality of the working environment, by applying the product only

at specific points. Product dispersion is avoided thanks to the closed spray box and the integration of the oil mist suction system. Last

but not least, the Promax installation and maintenance are very simple: no major interventions are required, simple operator controls, low

level input and cleaning ensure high uptime and correct functionality of the system.

Copyright© 2023 – www.dietronic.eu – All Rights Reserved – P.IVA: 04298080963 – Created by Gruppo Orange